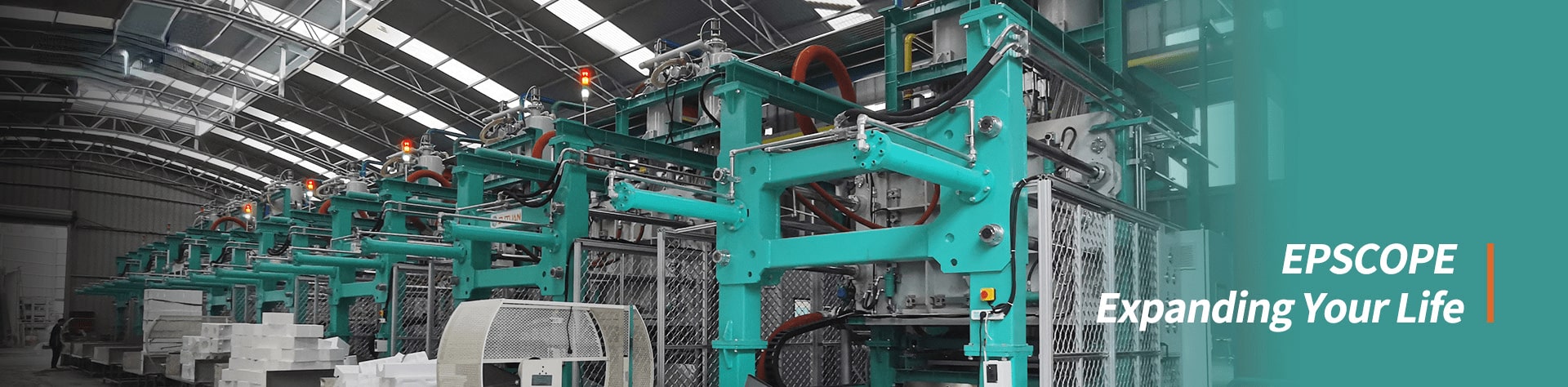

SUTUAN Machinery’s Successful EPS Machine Installations in South Africa

SUTUAN Machinery, a leading manufacturer of EPS machines, has successfully installed and commissioned EPS Shape Moulding Machine in South Africa for its clients.

Why they choose us then?

We are excited to share with you our successful client case in South Africa, where we provided our high-quality shape moulding machine. Our machine comes with a range of impressive features, including an advanced PLC system, an efficient hydraulic system, a reliable silo barrel, a precise heating system, a well-designed piping system, and a sturdy frame.

One of the standout features of our shape moulding machine is its advanced PLC system. It is based on Italian programming and has been designed to ensure maximum production stability and efficiency, while also reducing production costs. The system is controlled by the internationally renowned SIEMENS S1200 model PLC, which ensures a quick reaction time and stable operation. Additionally, the machine is equipped with a 15-inch pro-industrial touch screen, which has been framed by an aluminum alloy to maintain optimal performance in high-temperature environments. The control system program is easy to operate due to its simple design.

Our hydraulic system has been designed to be reliable and efficient. We have adopted an OEM hydraulic system from a professional Taiwanese manufacturer, which features an effective oil piping system and internationally recognized valves that ensure stable running of the oil cylinder. Additionally, we have refined the valve block to eliminate oil leaks for three years. We have also used refined oil piping, which improves the machine’s appearance and reduces the likelihood of pollution in the workshop.

The silo barrel is another impressive feature of our shape moulding machine. It has been designed to ensure quick and efficient material filling. It features several sealing crafts, which guarantee a strong seal for long-distance material filling. The filling process is completed in just 2-3 seconds, which saves compressed air.

Our heating system is precise and reliable, thanks to the use of German GEMU valves and digital proportional valve control. This enables the machine to shape with floating steam pressure, which controls the quality of EPS products. The system uses two valves to control the steam flow rate, which eliminates the need for frequent valve switching, and reduces the likelihood of component exchange due to valve life cycle damage.

Our piping system has been designed to ensure a smooth drain and is laid out without standing water. We have also included drain valves in the mould’s position, which ensures there is no standing water in the mould. This ensures that the product is heated quickly and stably, with low water content. As a result, there is no need for a heating room, which reduces steam consumption even further.

Finally, our shape moulding machine has a sturdy frame that is made from state-standard steel, which ensures its strength and durability. With its energy-saving features, our shape moulding machine can save 30-60 percent energy consumption with the same standard.

If you want to know more about EPS production lines, check out our article on “What is EPS Production Line“. You can also see our shape moulding machine in action on our YouTube channel .

South Africa market is one of our target markets with whatever EPS shape moulding machine or EPS block moulding machine.