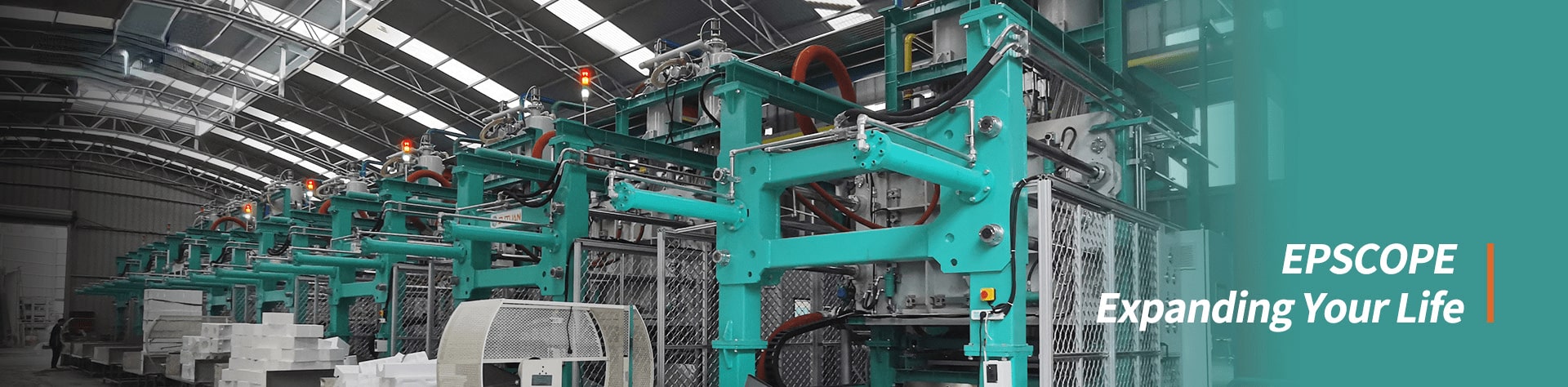

EPS (Expanded Polystyrene) block making machines are essential for the production of EPS blocks, which are used in a variety of applications such as construction, insulation, and packaging. Our client in South Africa was in need of a new EPS block making machine and reached out to us for a recommendation.

After evaluating our client’s needs and requirements, we recommended our vertical EPS block making machine. Our machine is designed with advanced features that provide several advantages over traditional horizontal EPS block making machines.

One of the main advantages of our EPS block making machine is its high production capacity. Our machine can produce up to 10 blocks per hour, making it ideal for large-scale production. In addition, our machine is designed with a user-friendly interface that makes operation and maintenance more straightforward, reducing downtime and increasing productivity.

Another advantage of our EPS block making machine is its low water content rate. Our machine is designed with an advanced heating system that uses less energy while still providing high-quality blocks. Once you would like to save steam cost one more, there is an optional steam recycle device, can be choosen for your customized eps production solution.

Our EPS block making machine is also designed with adjustable block size that allows for adjusting block to your ideal size, to help you with more business opportunities.

In conclusion, our vertical EPS block making machine provided several advantages for our client in South Africa. Its high production capacity, energy efficiency, user-friendly interface, fast mould change system, automatic block cutter, and safety features made it the perfect solution for our client’s EPS block making needs. If you’re in need of a new EPS block making machine, consider our high-performance option to meet your production needs.