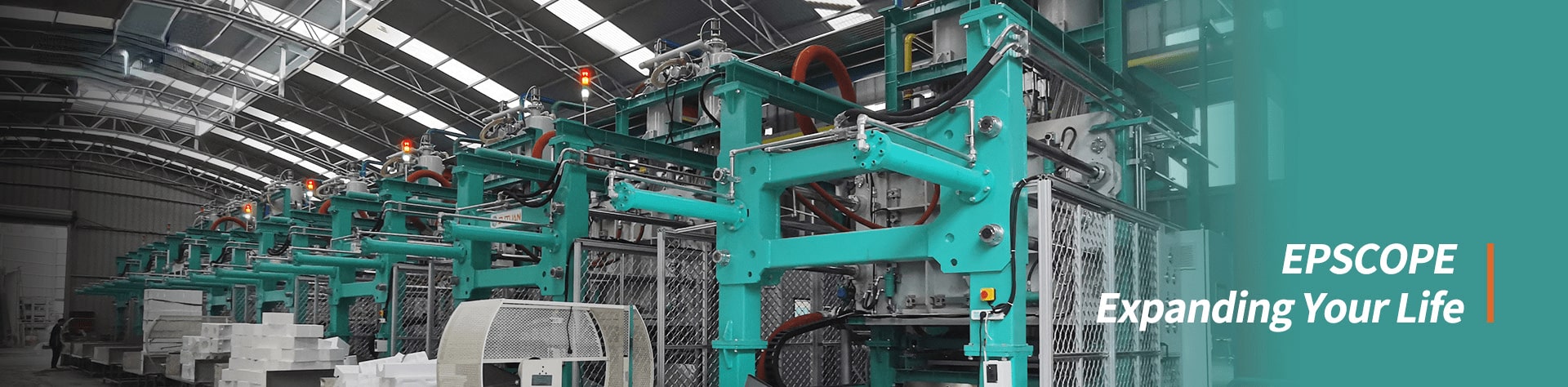

At the beginning, we should get a conception that there are two types of EPS production: EPS Board Manufacturing and EPS Shape Production.

These two types of production lines will be applied in different application. You could check with our “application article” for learning.

For a completed EPS factory, the followed machines will be required:

EPS board manufacturing: insulation material, building material in construction.

- 1.PRE‐EXPANDER

- 2.SILO SYSTEM

- 2.BLOCK MOLDING MACHINE

- 3.CUTTING MACHINE

- 4. AUXILARY EQUIPMENTS:

- 1).AIR COMPRESSOR

- 2).COMPRESSED AIR RECEIVER

- 3).STEAM BOILER

- 4).STEAM ACCUMULATOR

- 5).COOLING TOWER WORK FOR VACUUM COOLING

- 6).PIPING SYSTEM

EPS shaping manufacturing: cold chain transportation, vegetable box, fish box, seeding tray, appliance package etc.

- 1.PRE‐EXPANDER

- 2.SHAPE MOLDING MACHINE

- 3.MOLD

- 3.1).FILLING GUN

- 3.2).EJECTOR

- 4.SILO SYSTEM

- 5. AUXILARY

- 1).AIR COMPRESSOR

- 2).COMPRESSED AIR RECEIVER

- 3).STEAM ACCUMULATOR

- 4).STEAM BOILER

- 5).COOLING TOWER & PUMPS

- 6).PIPING SYSTEM

If you are interested in more or specific production line of yours own, welcome to leave a message or contact us!